Published on 2023-10-30 12:05 by Pouya Pournasir

Introduction

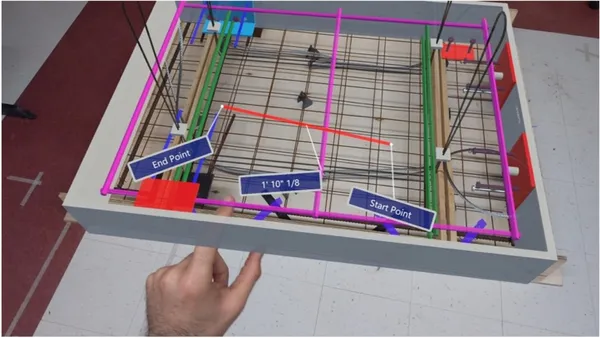

Precise inspection of construction products like concrete pre-casts demands meticulous attention to 2D blueprints. The slightest error can lead to significant time and energy wastage for construction companies. Leveraging Mixed Reality technologies holds promising potential in optimizing the inspection process, effectively reducing costs. In collaboration with Offsite Construction Research Centre (OCRC) and Spatial Computing Lab (SPECTRAL) from UNB, we have proposed a Mixed Reality solution to tackle this challenge. Our solution, tested with civil engineers using Microsoft HoloLens, demonstrated improved error identification, reduced cognitive workload, and a preference for our approach over traditional 2D blueprint analysis. This research project is funded by MITACS and Strescon Ltd.

Implementation

Our solution offers distinct advantages over conventional alternatives like Trimble software, primarily due to its utilization of the flexible Unity Engine platform. This allows companies to tailor the system to their specific requirements and offers the potential for additional feature integration. The solution is implemented by me.

In this prototype, we have created experimental features such as:

-

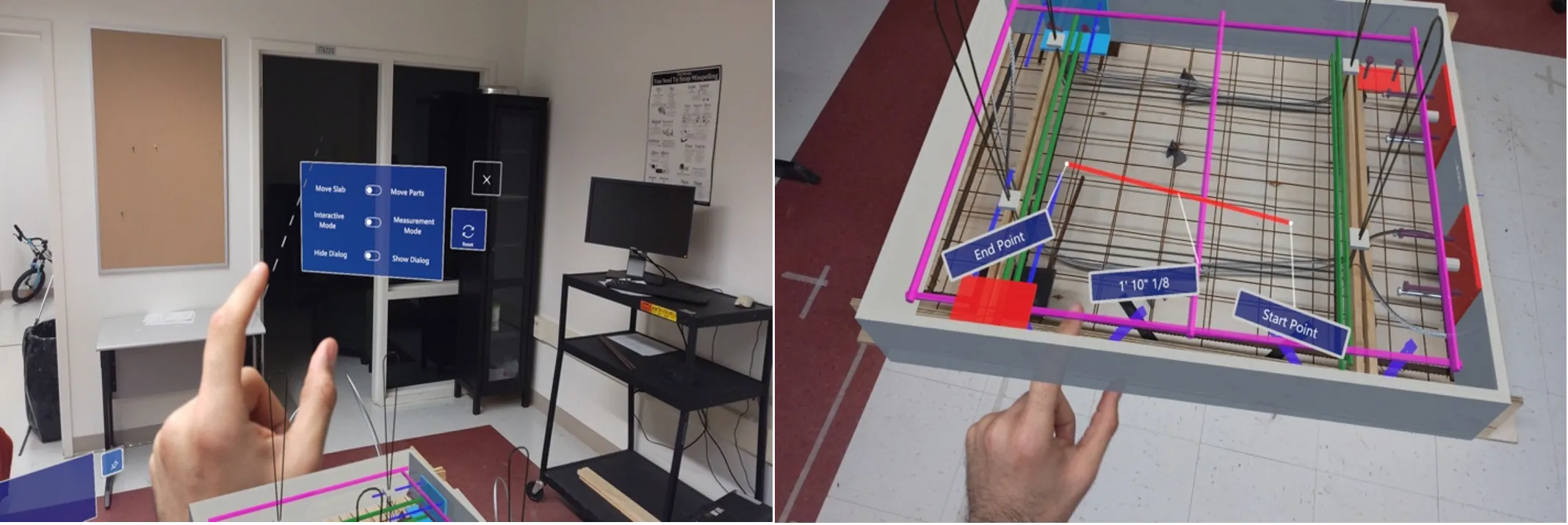

Dialog Pop-ups displaying detailed information for each component – See Figure 1.

-

Ability to hide and reposition individual components for a more detailed inspection.

-

Implementation of a dynamic Virtual Ruler to assist in measurements – See Figure 2

-

Integration of a Hand-Menu for convenient access to each feature.

-

Implementation of Speech Commands aimed at reducing cognitive workload.

-

Varied presentations of the 3D model, such as Overlay and Side-By-Side – See Figure 1.

These features collectively enhance the adaptability, accessibility, and functionality of our solution, providing construction companies with a comprehensive and customizable inspection tool.

Written by Pouya Pournasir

← Back to blog